Rumored Buzz on Motorcycle Parts New Zealand Specialists

Table of ContentsThe Facts About Motorcycle Parts New Zealand Specialists Uncovered3 Simple Techniques For Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsThe 4-Minute Rule for Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals ExplainedMotorcycle Parts New Zealand Specialists Fundamentals ExplainedThe Best Guide To Motorcycle Parts New Zealand SpecialistsThe 2-Minute Rule for Motorcycle Parts New Zealand Specialists

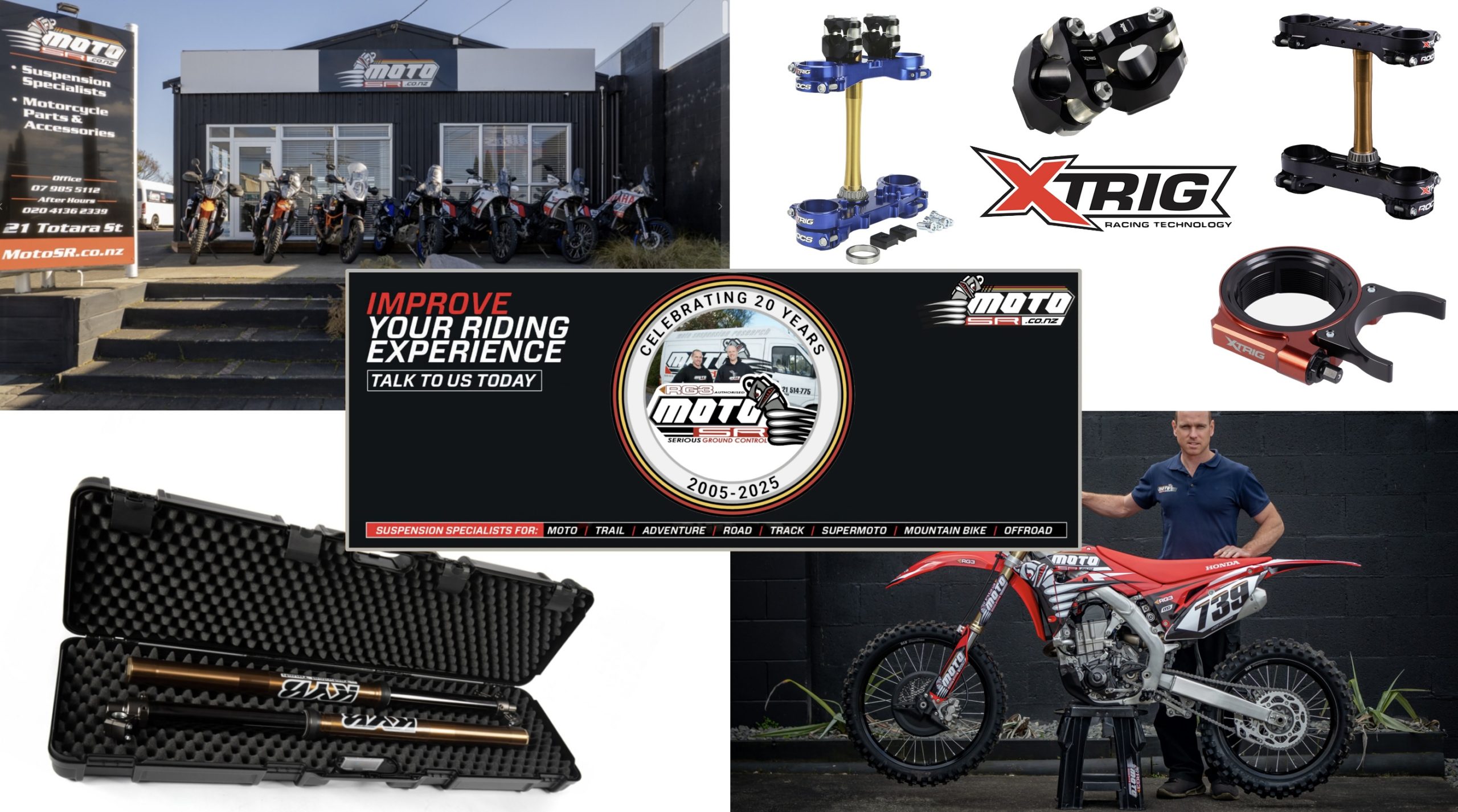

Reach out to one of our experts today.CNC machining innovation is rapidly becoming the prime focus of several production procedures around the globe as a straight outcome of its numerous benefits over other methods. Additionally, the markets that manufacture motorcycles have obtained on board with this trend. The most innovative business are now developing their engine elements and wheels utilizing machining strategies originally established for motorcycle components.

On the other hand, the results of industry are the main focus of this short article. Allow's obtain directly right into it. You might be questioning why we utilize. It is not difficult to fathom the variables that caused this outcome. Since we have your interest allow us explain the reasoning behind this modern-day growth in the motorcycle manufacturing sector.

The 6-Minute Rule for Motorcycle Parts New Zealand Specialists

Additionally, you have complete control over the look of the elements, even down to the min details. Occasionally, motorcyclists may determine to improve their trip by mounting aftermarket parts or customizing the bike's makeover. Once more, computer system numerical control (CNC) machining is one of the most functional approach. Upgrades may be of any kind of kind and style you desire.

The 7-Second Trick For Motorcycle Parts New Zealand Specialists

CNC machining might be used to make nearly all of a bike's metal and plastic components. To continue, we'll talk about numerous machined components for motorcycles.

Milling treatments are made use of to get the preferred level of wheel modification. An additional facet of the motorbike that may be individualized is the tires.

The Basic Principles Of Motorcycle Parts New Zealand Specialists

When it pertains to a car (or a motorbike), one of the most essential component is the engine. Numerous individuals mention it as the "heart" of the automobile. On the various other hand, the camshaft, the cylinder head, and the pistons tend to be elaborate and call for designs with a high level of accuracy.

Usage just high-grade products, however, because these lights are essential for the safety and security of motorcyclists and other chauffeurs or people on the road, particularly at evening. Bike headlights have three major components: the light bulb, or light source, the lens, and the housing.

Milling processes with a remarkable surface would certainly cause the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not made up of fragile materials; rather, it is built out of challenging polymers that can be machined right into more detailed patterns.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

Motorbike makers commonly cast these parts, but just for the manufacturing of bespoke components. Machining on 5 axes in today's globe is the methods by which any type of layout form might be understood.

Pick Runsom for your personalized bike components! We have the ability to make difficult and stylish parts making your bike matchless.

Below are a few instances of metals frequently made use of in motorbike component machining. Light weight aluminum is the main material used by business specializing in creating personalized bike components to create many of these parts - Motorcycle Parts New Zealand Specialists.

Zinc refers to an additional metal that is very light in weight and has terrific machining high qualities due to its high mechanical strength. This product may be created right into virtually any kind of shape and preserves its dimensions well. Even mission-critical elements that need a high degree of accuracy may profit from their use.

The Main Principles Of Motorcycle Parts New Zealand Specialists

Another steel that sees heavy usage in the manufacturing of CNC-customized parts is magnesium. It is among the lightest metals that are currently available and has outstanding machinability attributes and toughness appropriate with its reduced weight. Among Look At This the disadvantages of magnesium is that its dirt might conveniently catch fire.

Their most typical usage in generating various bike parts is bolts, such as screws and screws. Their reduced sensitivity to oxidation and rust makes look at this web-site them perfect for this use.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

It seems that CNC transforming and grating are the foundational processes. Alternate strategies exist, such as drilling. Allow's check out much of these machining strategies in deepness. The CNC transforming method is taken into consideration a subtractive production approach. On top of that, it needs keeping bars of product, usually plastic or steel, ready and after that twisting a cutting tool to eliminate areas of the material as the product is turned.

These methods are just as important and create elements with high precision and constant quality. The procedures imp source assist boost the total top quality of the machined bike components.

The 7-Second Trick For Motorcycle Parts New Zealand Specialists